Journal of Pharmaceutics & Pharmacology

Download PDF

Research Article

Preparation and Evaluation of Glaucocalyxin A Sustained- Release Pellets Based on Phospholipid Complex System with Enhanced Bioavailability

Miao YF1* and Sun JQ2

1College of chemistry and chemical engineering, Taishan University, China

2Office of Research Affairs, Taishan University, China

*Address for Correspondence: Miao YF, College of chemistry and chemical engineering, Taishan University, Tai’an, China; E-mail: lanjin0309@163.com

Submission: 20 June 2020;

Accepted: 05 August 2020;

Published: 07 August 2020

Copyright: © 2020 Miao YF, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Objective: Glaucocalyxin A (GLA) suffers from low oral bioavailability

and rapid in vivo metabolism. Therefore, the purpose of this study

was to develop a new formulation to enhance the oral bioavailability

simultaneously sustained release of GLA.

Material and methods: GLA-phospholipid complex was firstly formulated

by solvent-evaporation method to improve the solubility of GLA.

Differential scanning calorimetry, powder X-ray diffraction, scanning

electron microscopy, and solubility study were used to characterize the

GLA-phospholipid complex. And then, the optimized GLA-phospholipid

complex was selected to prepare GLA-phospholipid complex

sustained release pellets by extrusion-spheronization and fluidized bed

coating technology. The prepared pellets were studied by in vitro drug

release study and administered to beagle dogs to evaluate the oral

bioavailability of GLA-phospholipid complex and GLA-phospholipid

complex sustained release pellets.

Results: The results illustrated that GLA in GLA-phospholipid complex was either molecularly dispersed or in an amorphous form with 13.8-fold water solubility than the free GLA. The pharmacokinetic studies in beagle dogs demonstrated that GLA-phospholipid complex and GLAphospholipid complex sustained-release pellets showed 2.19-fold and 2.07-fold improvement than the free GLA by oral dosage, respectively.

Further, steady plasma concentration, and prolonger Tmax were simultaneously obtained from GLA-phospholipid complex sustained release pellet.

Conclusion: These outcomes suggested that the combination of phospholipid complex and sustained release pellets could enhance the oral bioavailability and prolong the action time in vivo which provided a promising delivery system for GLA.

Keywords

Glaucocalyxin A; Sustained release pellet; Phospholipid complex; Bioavailability; Solubility

Abbreviations

GLA: Glaucocalyxin A; GLA-PLC 1: GLA-Phospholipid Complex; DSC: Differential Scanning Calorimetry; PXRD: PowderX-ray Diffraction; SEM: Scanning Electron Microscopy; GLA-PPM: GLA-Phospholipid Physical Mixture

Introduction

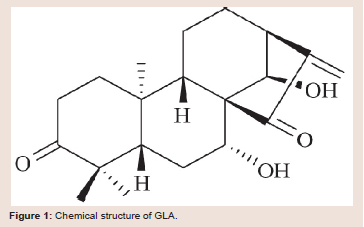

In the last two decades, about 40% of discovered active pharmaceutical ingredients either from the synthetic or natural origin suffers from low oral bioavailability [1-3]. This might be attributed to the low water solubility and/or permeability of drug across the biological membrane [4,5]. Glaucocalyxin A (GLA) is a biologically active ent-kaurane diterpenoid isolated from inulajaponica var, a traditional Chinese medicinal herb that grows in the northeastern of China [6,7]. The structure of GLA is shown in with molecular formula of 20H28O4 (Figure 1). GLA has been widely used in China folk medicine as cytotoxicity and antitumor, anti-bacterial, anti-inflammatory, stomachic and anthelmintic agent for more than 30 years [8].

However, there are two main disadvantages of GLA for its practical

use as a therapeutic agent, one is the poor water solubility caused

low oral bioavailability, the other is the rapid in vivo metabolism

which need the patient to take the medicine more than three times

a day [9,10]. To overcome the drawbacks, several strategies had

been proposed to increase the water solubility of GLA including

nanosuspensions [11], nanoparticle [12], inclusion complex [13], and self-nanoemulsion [14] etc.

Those researches demonstrated that when the GLA formulation

with a better solubility, GLA showed stronger antitumor activity

compared with the free drug [11,12]. Nevertheless, there was few

research focus on extending the action time of medicament within

human body along with improving the oral bioavailability of GLA. As

a result, there is an urgent demand to develop a new formulation with

prolonged actions and enhanced oral bioavailability of GLA.

In recent years, the technique of lipid-based drug delivery system, such as liposomes [15,16], solid lipid nanoparticles [17,18],

phytosomes etc. [19]. Have acquired more attention as they can

resolve major drawbacks related to drug delivery. However, there are

some shortcomings, like drug leakage, low drug loading, and poor

stability that remain to be a major concern for liposome. Similarly,

low inherent incorporation rate, high tendency for drug expulsion,

and unpredictable gelation tendency of solid lipid nanoparticles

restrict their overall utilization [20,21]. Besides that, the related

manufacturing process is sophisticated and difficult to scale up.

Among these, the drug-phospholipid complex has become one of

the most successful strategies for improving the oral bioavailability

of a number of poorly water soluble drugs by enhancing solubility,

permeability, and by improving metabolic stability in gastrointestinal

tract [22-24]. Being comprised with such property, phospholipid

complex is a suitable delivery vehicle for drugs which have limited

solubility (BCS class II) limited permeability (BCS class III), and both

(BCS class IV). Meanwhile, it is relatively cheap, easy to formulate,

and easy to scale up compared with other lipid-based drug delivery

systems [25].

Spherical free-flowing pellets, as multiple unit sustained release

drug reservoirs of narrow size distribution are popular in commercial

products. The pellets offer many clinical advantages compared with

single unit dosage forms, such as less variability release profiles [26],

stable plasma concentrations [27], reduced intra-and inter-subject

variability on drug plasma [28], decreased local irritations, less dose

dumping risk and great reproducibility [29].

Therefore, in this study, in order to enhance the oral bioavailability

and prolong the action time of GLA in vivo, we developed a novel

GLA-Phospholipid Complex (GLA-PLC) sustained release pellets

formulation to take advantage of the solubility and absorption

enhancing effect of phospholipid complex and release rate-controlling

capacity of the sustained release pellets.

Materials and Methods

Materials:

Glaucocalyxin A was obtained from College of Pharmaceutical

Science, Soochow University (Suzhou, China). Lipoid E80 (trade

name of phospholipid)was purchased from Shanghai Dongshang

BiologyTechnique Ltd. (Shanghai, China). Lactosewas purchased

from Meggle. (Germany). Kollicoat SR 30 D was purchased from

BASF (Germany). Unless otherwise stated, all other materials were

of analytical grade.Preparation of GLA-PLC:

Solvent evaporation method was applied to prepare GLA-PLC.

In short, GLA-PLC was prepared with drug and phospholipid

in 1:0.5, 1:1, 1:2, or 1:3 molar ratios. Accurate quantity of GLA

and phospholipid were taken in a 250 mL round bottom flask and

dissolved in anhydrous ethanol to obtain uniform solution with the

drug concentration of 2 mg/ml, 5 mg/ml, 10 mg/ml, 15 mg/ml, or 20

mg/ml. The prepared mixture solution was refluxed at 25 0C, 30 0C,

40 0C, 50 0C or 60 0C for 0.5 h, 1 h, 1.5 h, 2 h, 3 h or 4 hunder constant

stirring at 100 rpm to form GLA-PLC. Subsequently, anhydrous

ethanol was evaporated by rotary evaporation under reduced pressure

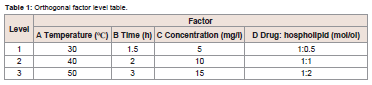

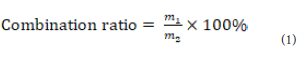

to give solid product.Based on the single factor experiment, GLA-PLC preparation conditions were optimized by L9 (34) orthogonal experiment, which

can be found in Table 1. The dried residues were placed in a desiccator

in room temperature until used.

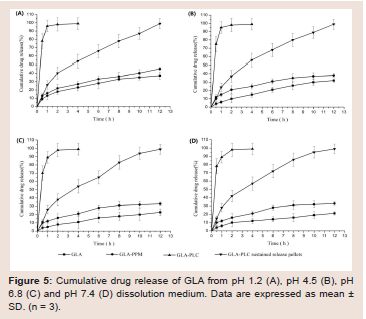

Figure 5: Cumulative drug release of GLA from pH 1.2 (A), pH 4.5 (B), pH 6.8 (C) and pH 7.4 (D) dissolution medium. Data are expressed as mean ± SD. (n = 3).

The same ratio of GLA and phospholipid was simply mixed to

form GLA-phospholipid physical mixture (GLA-PPM). The resulting

samples was stored in a desiccator in room temperature until used.

The combination ratio of GLA-PLC:

The combination ratio of GLA to phospholipid was measured

under the difference of solubility between GLA and GLA-PLC [30].

GLA-PLC could be dissolved in n-hexane, but free GLA could not be

dissolved in n-hexane. The combination ratio was calculated on the

following basic equation (Eq. (1):Where, m1 is the combination amount of GLA in the GLA-PLC,

and m2 is the total amount of GLA in the GLA-PLC.

Characterization of GLA-PLC:

Determination of GLA content in phospholipid complex: The

content of GLA in the complex was determined by reversed-phase

HPLC method (Agilent 1260, Agilent Technologies, Inc., USA)

using a Phenomenex Luna C18 column (4.6 mm × 250 mm, 5μm)

and a 1.0 ml/min flow rate, a 20 μl injection volume, a 40 0C column

temperature, 231 nm UV detection. The mobile phase was comprised

of acetonitrile and water in a volume ratio of 35:65.Solubility studies: Solubility determination of GLA, GLAPPM,

and GLA-PLC were carried out by adding excess of the above

samples to 10 ml of distilled water and n-octanol in sealed glass vials,

respectively. Each experiment was performed in triplicate. After 12

h of shaking in the shaker at 100 rpm under 37 0C, the solution was

centrifuged at 10,000 rpm for 5 min and the obtained supernatants

were filtered (0.45 μm, Jinlong, Tianjin, China). The concentration

of GLA in the resulting solution was diluted with mobile phase and

analyzed by HPLC as described in “2.4.1 Determination of GLA content in phospholipid complex”.

Differential scanning calorimetry (DSC): Thermal characteristic

of GLA, phospholipid, GLA-PPM, and GLA-PLC were determined

using an ATA449-C instrument (NETZSCH, Selb, Germany) under

a 10 ml/min stream of nitrogen gas flow. About five milligrams of the

samples were heated from 40 0C to 400 0C at the heating rate of 10 0C

/min in an open aluminum pan.

Powder X-ray diffraction (PXRD): The PXRD patterns of GLA,

phospholipid, GLA-PPM, and GLA-PLC were obtained on a D/MAX

2500-PC X-ray powder diffraction meter (Rigaku Denki, Tokyo,

Japan), with a voltage of 50 kV and a current of 40 mA. Data was

scanned from 5° to 40° (2θ) with a step size of 0.02°.

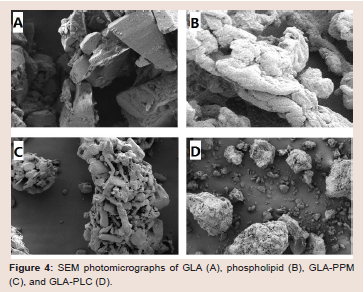

Scanning electron microscopy (SEM): The surface morphology

of GLA, phospholipid, GLA-PPM, and GLA-PLC were examined

using anS-4100 scanning electron microscope (Hitachi, Tokyo,

Japan). Samples were sputter coated with gold-palladium and

observed at different magnifications.

Preparation of GLA-PLC sustained release pellets:

GLA-PLC sustained release pellets were conducted by extrusionspheronization

and fluidized bed coating technology by the following steps: first, GLA-PLC was mixed with lactose in 1:0.5 weight ratio to

get free flowing powder and then sieved by a 60 mesh. Second, the

prepared powder was moistened by purified water in order to get

soft material. This soft material was extruded by extruder (Guanlian

Pharmaceutical Equipment Co., Ltd., Shanghai, China) with dies of

1.0 mm diameter and extrusion speed of 30 rpm. The extrudates were

then placed in a spheronizer fitted with a cross-hatched plate rotated

for 15 min at a spheronization speed of 1000 rpm. The spheronized

pellets were sieved after had been dried in fluidized bed processor

(Niro-Aeromatic, Switzerland) at 50 0C for 25 min.

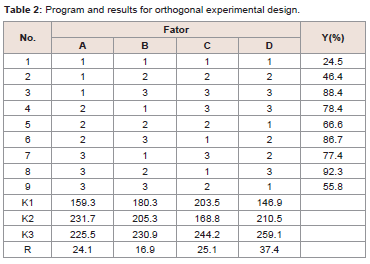

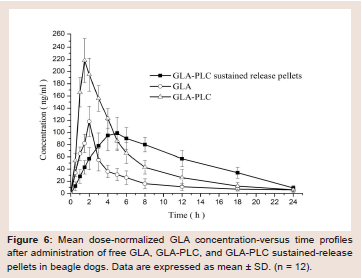

Figure 6: Mean dose-normalized GLA concentration-versus time profiles

after administration of free GLA, GLA-PLC, and GLA-PLC sustained-release

pellets in beagle dogs. Data are expressed as mean ± SD. (n = 12).

Finally, the pellets were coated through fluidized bed coating

technology as described by PateL SA et al. with some modifications

[31]. The coating polymer suspension was prepared by adding16 g

triethyl citrate (as plasticizer) and 530 g Kollicoat SR 30 D to 430 g

purified water with stirring for 40 min. 55 g talc was added to the

above suspension as an anti-tacking agent. The coating suspension

was stirred during the coating process. The coating was done at

10% weight gain using a laboratory-scale fluid bed coater (Hanse,

Changzhou, China).Experimental parameters were pre-warming of

core pellets at 40 0C for 10 min; atomizing air pressure 1.2 bars; spray

nozzle diameter 1.2 mm; air flow rate 90 m3.h-1; inlet air temperature

50-55 0C; product temperature 35-40 0C; spray rate 0.5 ml.min-1; post

drying at 55 0C for 15min.

In vitro drug release:

The drug release profiles of GLA, GLA-PPM, GLA-PLC, and

GLA-PLC sustained-release pellets (all those formulations contained

20 mg GLA were filled into hard gelatin capsules) were studied using

Chinese Pharmacopoeia type Ⅲ Apparatus (Tianjin Tianda Tianfa

Technology Co., Ltd, Tianjin, China), paddle method with big vessel,

at the paddle rotation speed of 50 rpm in 900 ml dissolution medium,

at 37 ± 0.5℃. At the predetermined times, 1 ml aliquot was withdrawn,

filtered (0.45 μm, Jinlong, Tianjin, China), and analyzed by reversedphase

HPLC method as described in “2.4.1 Determination of GLA

content in phospholipid complex”. 1.0 ml of fresh dissolution media

pre-warmed to 37 0C 0.5 0C was replaced into the dissolution medium

after each sampling. All the experiments were performed in triplicate.Pharmacokinetic studies in dogs:

The in vivo pharmacokinetic study described here was reviewed

and approved by the Nanjing Medical University Institutional

Animal Care and Use Committee (No. 2019-0306) and adhered to the

“Principles of Laboratory Animal Care”. Tofacilitate administration,

GLA, GLA-PLC, and GLA-PLC sustained release pellets were filled

into hard gelatin capsules, each dosage contained 20 mg GLA.An open label, randomized, three-period crossover experiment

design was adopted to evaluate the pharmacokinetics of the prepared

capsules. Twelve male beagle dogs weighting 10 ± 1 kg were divided

into three group and tested under fasted state (with free access to water). The prepared capsules were administered to beagle dogs in

the morning with 60 ml of tap water by an oral gavage. After dosing,

the dogs were returned to metabolism cages with free access to water.

They were provided with standard food after the 12 hours sampling

time point.

A total of 5 ml of the whole blood samples were taken from

the jugular vein via 20 gauge needle of the dogs before and at the

following time points after dosing: 0.5, 1, 1.5, 2, 3, 4, 6, 8, 10, 12, 16,

and 24 h. Plasma was obtained by centrifuging for 10 min at 4000

rpm, and was stored in a freezer at -20 0C before analysis.

The samples were extracted using the following procedure:

plasma (1.0 ml) was mixed with 50 μl oridonin methanol solution

(0.5 μg/ml) as an internal standard, and 6.0 ml ethyl acetate in a 10

ml plastic centrifuge tube, centrifuged at 4000 rpm for 10 min to

precipitate the proteins and the supernatant layer was evaporated in a

rotary centrifugal vacuum evaporator. The residue was reconstituted

in 100 μl mobile phase and 20 μl of the resulting solution was analyzed

by HPLC-UV method, as described in the section “Determination of

GLA content in phospholipid complex”.

Analysis of data:

The pharmacokinetic parameters were calculated by DAS 2.0

software. All values were expressed as the mean ± SD. Statistical

analysis was carried out using Student’s t-test. Significant difference

was regarded as p<0.05.Results and Discussion

Preparation of GLA-PLC:

A good amount of aprotic organic solvents can be used as reaction

solvents to prepare phospholipid complex, for instance, methanol,

ethanol, tetrahydrofuran, acetone and so on [32,33]. In this study,

as a way to reduce the harm to human body or our environment,

more safety anhydrous ethanol was chosen as the solvent during the

process of GLA-PLC.From the single factor experiment we can know that when the

reaction time further increased, there was no obviously difference

in the drug-phospholipid combination ratio (The combination ratio

were 31.2%, 62.4%, 72.8%, 91.3%, 91.5%, and 91.2% for 0.5 h, 1.0 h,

1.5 h, 2.0 h, 3.0 h, and 4.0 h, respectively.). On the other hand, due to

the thermal stability of phospholipid, when the reaction temperature

rose over 60 0C, the combination ratio was declined. Moreover,

the combination ratio was declined when the GLA concentration

exceeded 10 mg/ml. This phenomenon was due to the excessively high

concentration of the two material in the system, which may result

in insufficient contact of GLA with phospholipid in the solvent. The

combination ratio was increased with the increase of phospholipid

proportion. The experimental data were 45.6%, 85.8%, 89.4%, and

91.3% for GLA and phospholipid in 1:0.5, 1:1, 1:2, and 1:3 molar

ratios, respectively.

The optimal formulation and processing parameters to obtain the

maximum combination ratio of GLA-PLC were selected by orthogonal

experiment design. Theoretically, the optimum conditions for the

preparation of GLA-PLC were A2B3C3D3.The results are shown in

Table 2. In order to validate it, three batches were performed using the optimized preparation conditions (reaction temperature 40 0C,

reaction time 3 h, concentration 15 mg/ml, GLA: phospholipid 1:2).

The combination ratio of each batch of GLA-PLC was 94.6%, 95.3%,

and 95.0%, respectively.

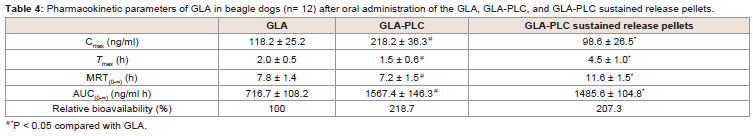

Table 4: Pharmacokinetic parameters of GLA in beagle dogs (n= 12) after oral administration of the GLA, GLA-PLC, and GLA-PLC sustained release pellets.

Characterization of GLA-PLC:

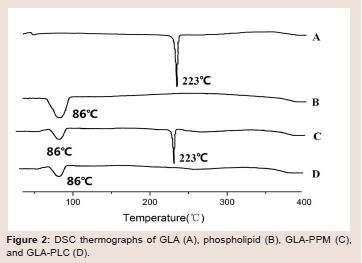

Differential scanning calorimetry (DSC): DSC is a fast and

reliable thermo-analytical technique to obtain distinct information on

the polymorphism and crystallinity of the molecular interaction based

on a change in the sharp of peak. Figure 2 presents the DSC curves

of GLA (A), phospholipid (B), GLA-PPM (C) and GLA-PLC (D).

As shown in Figure 2, GLA showed one sharp endothermic peaks at

223 0C, suggested that it’s crystalline state. The phospholipid displays

a broad endotherm at 860 corresponding to its phase transition.

GLA-PPM exhibited two peaks at 86 0C and 223 0C corresponding

to phospholipid and GLA, respectively. However, the endothermic

peaks at 223 0C was disappeared in the DSC of GLA-PLC (Figure 2D), demonstrating the occurrence of molecular interactions between

GLA and phospholipid. These results indicated that there was no

crystallization of GLA in the GLA-PLC, GLA may be dispersed

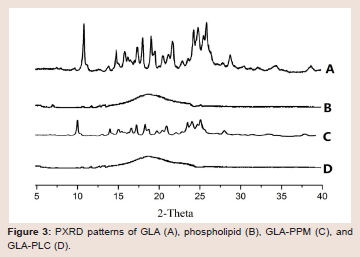

molecularly or amorphously in the phospholipid molecule.Powder X-ray diffraction (PXRD): Figure 3 showed the powder

X-ray diffraction patterns of GLA (A), phospholipid (B), GLA-PPM

(C) and GAL-PLC (D). The spectrum of GLA exhibited numerous

sharp diffraction peaks, indicating that the GLA was present as

a crystalline pattern. No peaks were detected in the spectrum of

phospholipid, which illustrated its amorphous nature. The diffraction

pattern of the GLA-PPM revealed the characteristic peaks of

GLA, suggested that simple physical mixing had no effect on the

interaction between GLA and phospholipid. On the other hand, all

the crystalline peaks had disappeared in GLA-PLC, indicated that

GLA in a phospholipid matrix was either molecularly dispersed or

in an amorphous form [34], which was consistent with the result of

the DSC.

Scanning electron microscopy (SEM): The representative

surface morphology of GLA (A), phospholipid (B), GLA-PPM (C)

and GLA-PLC (D) are presented in (Figure 4). GLA appeared as

smooth-surfaced rectangular crystalline structures with different

size and the similar crystal structure can be observed in the physical

mixture. For GLA-PLC, the morphology was changed completely

and rectangular crystalline structures were not observed, indicating

that GLA was transformed into an amorphous state.

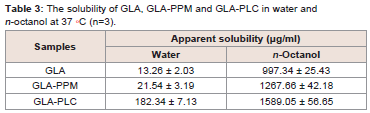

Solubility studies:

From the data in Table 3, we can conclude that the solubility of

GLA-PLC in water and n-octanol increased significantly (P < 0.01)

in comparison with GLA. The solubility of the GLA-PLC and GLAPP

Min water was about 13.7 times and 1.6 times higher than GLA. This improvement in solubility could be explained by the amorphous

form of GLA and the amphipathic nature and solubilizing effect of

phospholipid. In addition, the date illustrated that the solubility of

GLA-PLC in n-octanol was slightly increased than GLA, which in

turn might result in improved absorption across the gastrointestinal

tract. In short, the solubility of GLA-PLC increased in water and

n-octanol means that the drug could be well dissolved and absorbed

in gastrointestinal tract.Preparation and in vitro drug release of GLA-PLC sustainedrelease pellets:

Enhancement of the drug solubility in the inner compartment

aided the control of the drug release by the outer rate-controlling

membrane onto the pellets was the main technical route in this

article. In order to design the reservoir-type sustained release pellets,

the poorly water soluble GLA was prepared into GLA-PLC which

were used as the core material for the layering process. For facilitate

the preparation of pellets, lactose was added to GLA-PLC to get freeflowing

powder, due to the viscous property of phospholipid. Talc

was used as lubricants to prevent aggregation between the pellets and

improve powder flow properties. The pellets core were prepared by

extrusion-spheronization method, which is one of the conventional

methods used since years in pharmaceutical industry [35,36].Enhancement of the drug solubility in the inner compartment

aided the control of the drug release by the outer rate-controlling

membrane onto the pellets was the main technical route in this

article. In order to design the reservoir-type sustained release pellets,

the poorly water soluble GLA was prepared into GLA-PLC which

were used as the core material for the layering process. For facilitate

the preparation of pellets, lactose was added to GLA-PLC to get freeflowing

powder, due to the viscous property of phospholipid. Talc

was used as lubricants to prevent aggregation between the pellets and

improve powder flow properties. The pellets core were prepared by

extrusion-spheronization method, which is one of the conventional

methods used since years in pharmaceutical industry [35,36].

Pharmacokinetic studies in dogs:

The plasma concentration-time profiles of GLA in beagle dogs

following the oral administration of GLA, GLA-PLC, and GLA-PLC

sustained release pellets are presented in (Figure 6), and the major

pharmacokinetic parameters are summarized in Table 4. From

the data we can know that the plasma concentration of GLA from

GLA-PLC exhibited a higher Cmax (218.2 ± 36.3 ng/ml, 1.85-fold) in

comparison with free GLA (118.2 ± 25.2 ng/ml). AUC(0-∞) of GLA in

GLA-PLC (1567.4 ± 146.3 ng/ml h) was significantly higher than that

of the free GLA (716.7 ± 108.2 ng/ml h), with 2.19-fold increased oral

bioavailability.Additionally, the maximum plasma concentration obtained from

GLA-PLC sustained-release pellets were reach at 4.5 ± 1.0 h and

decreased more slowly than that of free GLA and GLA-PLC capsule.

The AUC(0-∞) of GLA-PLC sustained release pellets were 1485.6 ±

104.8 ng/ml.h (2.07-fold), in contrast to 716.7 ± 108.2 ng/ml h of free

GLA. In the present case, enhanced oral bioavailability of GLA was

achieved by phospholipid complex with the relative bioavailability of

GLA-PLC and GLA-PLC sustained-release pellets were 218.7% and

207.3% compared with the free GLA, respectively.

Pharmacokinetics findings demonstrated that GLA-PLC and

GLA-PLC sustained-release pellets showed better absorption rate,

and/or sustained release behavior in vivo than free GLA. This may be

attributed to the following reasons:

(1) Compared to crystalline state of GLA, an amorphous state

of GLA in GLA-PLC had better solubility and in vitro drug release

profiles of GLA;

(2) Phospholipids being an important component of cell

membrane to maintain the fluidity of cell membrane and owing to

the amphiphilic nature, the GLA-PLC are considered to penetrate the

cell membrane and enter the cytoplasm of living mammalian cells

without disturbing the cellular lipid bilayers;

(3)The combination of GLA to phospholipids can enhance the

absorption of GLA through lymphatic pathway and may reduce the

exposure of the GLA in the gastrointestinal tract and protect the GLA

from degradation by the enzymes [37,38].

(4) The coating layer formed a good barrier membrane to control

the drug release from the pellets.

Conclusion

In this paper, GLA-PLC and GLA-PLC sustained-release pellets

were successfully prepared for the first time. The physicochemical

characteristics of GLA-PLC were indicated by DSC, PXRD, and

SEM techniques and the studies showed that GLA in a phospholipid

matrix was either molecularly dispersed or in an amorphous form.

Our research based on solubility and in vitro drug release studies

clearly demonstrated a higher solubility and complete drug release

profiles for GLA-PLC than free GLA. Besides that, GLA-PLC

sustained-release pellets exhibited sustained release characteristics

with over 95% total release in 12 h. The pharmacokinetic studies in

beagle dogs demonstrated that GLA-PLC and GLA-PLC sustainedrelease

pellets showed 2.19-fold and 2.07-fold improvement than

the free GLA by oral dosage in beagle dogs. Further, enhanced oral

bioavailability, steady plasma concentration, and prolonger Tmax were

simultaneously obtained from GLA-PLC sustained release pellets,

indicating a promising way to achieve the optimal oral bioavailability

with sustained release property for poorly water soluble drugs.