Journal of Veterinary Science & Medicine

Download PDF

Research Article

Optimization of Chitin Extraction, Physicochemical and Functional Properties of Chitosan Production from Shells of Karamote Shrimp Peneaus (Melicertus) Kerathurus in Western Greece

Katsoulis K1* and Rovoli M2

1Department of Animal Husbandry and Nutrition, University of

Thessaly, Greece

2Biochemistry Department, University of Thessaly, Greece

*Address for Correspondence: Katsoulis K, Assistant Professor, Department of Animal Husbandry and Nutrition, University of Thessaly, Faculty of Veterinary Science, 224 Trikalon Street, P.O. Box 199, Karditsa, 43100, Greece; E-mail: kkatsoulis@uth.gr

Submission: 12-December, 2020;

Accepted: 25-January, 2021;

Published: 28-January, 2021

Copyright: © 2021 Katsoulis K, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

This research aims to optimize by chemical methods the extraction of chitin and chitosan from shells of Karamote shrimp Peneaus (Melicertus) kerathurus. Shrimp waste can be used as source of high value compounds. Chitin is a major component of the exoskeleton

of invertebrates and chemically is a linear polysaccharide of β (1→4)

linked N-acetylglucosamine monomers. Chitosan is a deacetylated

form of chitin having d-glucosamine repeating units linked by β (1-4)

glycosidic bond. The extraction method uses different concentrations

of sodium or potassium hydroxide in the deproteinization (protein

separation) and deacetylation (remove acetyl groups) step and

hydrochloric acid for demineralization (separation of calcium

carbonate and calcium phosphate) to yield optimum output. Among

all experiments, results of 1.0 N solution of HCl for demineralization, 2

N for deproteination and 12.5 N NaOH solutions for deacetylation at

solid to solvent ratio of 1: 15, clearly demonstrate a significant yield of

chitin and chitosan. The results obtained from this study show also that

the solubility of chitosan in 1% acetic acid solution achieved up to 90%.

Keywords:

Fishery byproducts; Chitin; Chitosan; Shrimp shell; Deacetylation

Introduction

In recent years great interest has been expressed in isolating

components using by-products and wastes. Fish wastes include

byproducts or many fish species having no or low commercial

value, undersized or damaged commercial species. Large amounts

of culture wastes are associated with the environmental impact

on aquatic ecosystems, since the release of organic wastes might

significantly change the community structure and biodiversity of the

benthic assemblages [1,2]. The objective of reducing fishery discards

and to avoid environmental problems can be achieved by establishing

alternative solutions, such as technologies to enhance and transform

fish wastes as an economic resource, for example by developing

techniques of extraction and concentration of the bioactive compounds

they contain. Crustaceans, belonging to the Decapoda order, include

prawns, shrimps, lobsters, crayfish and crabs. Melicerthus kerathurus

known as karamote prawn is one of the above group. It is a demersal

crustacean, widely distributed inhabiting the Mediterranean Sea

and the eastern Atlantic from the south coast of England to Angola

where it lives on soft bottoms of the continental shelf, less than 60

m depth [3]. The shell of crustaceans consists of 20-30% chitin, 30-40% protein and 30-50% calcium carbonate and calcium phosphate,

and other minor constituents, such as lipids, astaxanthin and other minerals [4]. Chitin and chitosan are β (1-4) glycans whose chains are

formed by 2-acetamide-2-deoxy-D-glucopyranose and 2-amino-2-

deoxy-D-glucopyranose units, respectively. Chitin is the second most

abundant polysaccharide on earth, following the cellulose. Chitin can

be obtained from the cell wall of fungi, the exoskeleton of arthropods,

the shells of mollusks and the beaks of cephalopods including

cuttlefish, octopuses and squids. Chitin is presented mainly in three

allomorphs: α-chitin, with antiparallel chains, is the most abundant

and it is isolated from the exoskeleton of crustaceans, particularly

from shrimps and crabs; β-chitin, with parallel chains, is presented in

the cell walls of diatoms and in the skeletal structures of cephalopods,

and commonly extracted from squid pens; γ-chitin is presented in

fungi and yeast, which is a combination of the α and β allomorphs

[5]. Chitosan is generally prepared by the deacetylation of chitin with

alkali. Due to their useful biological properties (biocompatibility,

biodegradability, antimicrobial activity) and chemical modification

potentials because of their reactive functional groups (-OH, -NH2,

and -COOH) both have been used in a wide range of fields including

biomedical, food production, and wastewater treatment fields [6-8].

The current research was performed to evaluate the suitable acid and

alcali concentration for extraction of high-quality chitin and chitosan

from shells of Melicertus kerathurus.

Materials and Methods

Description of the fishing area: The experimental fishery of the shrimps was carried out twice

in October 2019 in Kalamos channel, along the Western Greek

coast of the Ionian Sea, near the Kalamos Island (Lat.38.61581o

Ν, Log.20.90102o Ε). Administratively, the island belongs to the

Prefecture of Lefkada Island covering an area of 25 km2.

Raw material: A total number of 234 specimens were collected. Firstly, the

shells were removed from the animal and secondly the specimens

were packed in polyethylene bags, placed on ice, transported to the

laboratory and were stored in a freezer at -20 °C until further use.

Reagents: All the chemicals and solvents used were purchased from Sigma-

Aldrich at the analytical grade or highest level of purity available and

used as received. A commercial chitosan with a deacetylation degree

of 75% was chosen. All solutions were freshly prepared in distilled

Methods

Laboratory sample preparation was needful to convert the

shell sample into a homogeneous material suitable for analysis.

Before grinding, the biggest parts of shell samples were crushed and

divided in smaller. Drying of samples was obtained by heating in a

drying oven (model R. Espinar, S.L.) at 100-103 °C until constant

weight was obtained between two sequential measurements [9,10].

Drying samples grinded in a mill (System POLYMIX® PX-MFC

90 D) into smaller particles using sieve with 2 mm wide openings.

pH measurements were made using a digital laboratory pH meter

(model WTW pH 525) which was calibrated using certified pH= 4.0

and pH= 7.0 buffer solutions, according to the official method [9].

The Ether Extract (EE) was determined using method of Soxhlet.

Approximately 2000 mg of solid sample were mixed with anhydrous

sodium sulfate, placed in an extraction thimble and were extracted

using an appropriate solvent in the Soxhlet extractor. The distilled

solvent was condensed and in final drying step the remaining traces

of solvent was evaporated from the boiling flask. The mass of the

extract (total fat) was measured after subtracting initial from final

weight of the boiling flask. Ash contents were determined using dry

ashing method. The samples (2000 mg) were ashed for about 8 hr.

until a white or grey ash residue had been obtained using a furnace (model P. Selecta, 3000 W) where temperature had been gradually

increased from room temperature to 450 °C in 1 h [9,10]. The

solubility of chitosan was carried in dilute solution of acetic acid. 1000

mg of chitosan obtained from the deacetylation process was dissolved

in 100 mL of 1% acetic acid solution and stirred by magnetic stirrer

until a homogeneous solution was obtained. The chitosan acidic

solution was then filtered using a vacuum pump. The procedure was

repeated three times. The insoluble content was calculated from the

weight of insoluble particles obtained on the filter and the weight of

chitosan dissolved. The water binding capacity (wbc) was calculated as

follows; 10 ml of distilled water with 1000 mg of chitosan was mixed

on a vortex for 15 min and centrifuged at 3500 rpm for 30 min. After

centrifugation, supernatant water was poured off and the sample was

weighed. WBC (%) = [Bound water (g)/Initial chitosan weight (g)]

* 100. The oil binding capacity (obc) was calculated as follows; 10 ml

of sunflower with 1000 mg of chitosan was mixed on a vortex for 15

min and centrifuged at 3500 rpm for 30 min. After centrifugation,

supernatant oil was poured off and the sample was weighed. OBC (%)

= [Bound oil (g) / Initial chitosan weight (g)] * 100 [10].

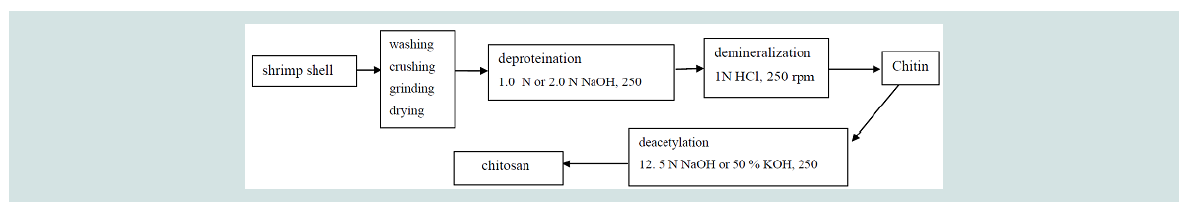

Extraction of chitin by chemical method: Deproteination (Dp): A total of 5-20 g dry samples of raw

shrimp shell waste were treated with 1.0 N and 2.0 N NaOH at solid

to solvent ratio 1:5, 1:15, 1:18 and 1:20 (w/v), with constant stirring at

200 rpm for 24 hours at room temperature, with pH ranged from 11-13. After that, the solution was filtered and the samples were washed

with distilled water to neutrality in running tap water. Water from

the samples was removed before performing the demineralization

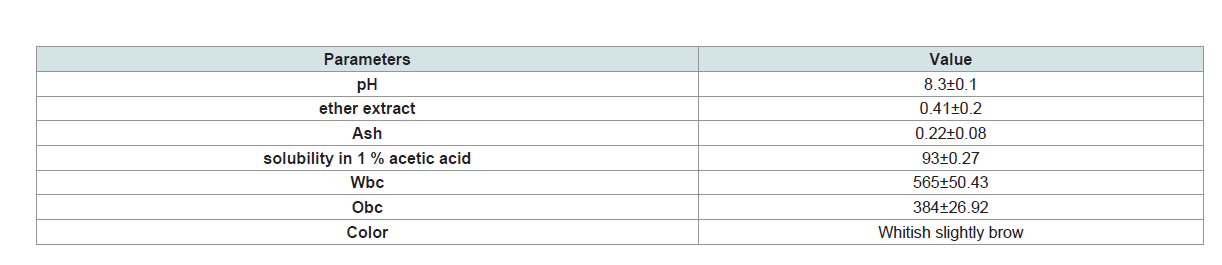

Table 3: Physicochemical and functional properties of chitosan (values are expressed as Mean± S.D (n=5).

Demineralization (Dm): Samples from deproteination process

were treated with 1.0 N HCl in the ratio 1:10 (w/v), with constant

stirring at 200 rpm for 24 hours with pH value ranged pH 1.0-2.5

at room temperature. After that, the solution was filtered and the

samples were washed with distilled water to remove acid and calcium

chloride. The samples were then dried for 3 hours using an oven at

80 oC until constant weight was obtained. The dried sample is now

known as chitin.

Chitosan production:

Deacetylation (Da): The deacetylation process was conducted

by soaking dried chitin prepared from demineralization in a 12.5 N

solution NaOH and 50% (w/v) solution KOH with constant stirring

at 200 rpm for 24 hours at room temperature. After that, the product

is known as chitosan. Chitosan was washed with tap water until

neutral (pH 6.5-8.0) and dried as described in deproteination and

demineralization.Chitin and chitosan yield:

The percentage of the yield of chitin was calculated by dividing the weight of extracted chitin to initial dry shrimp shell weight.Yield was calculated as follows: Yield of chitin (%) = (extracted

chitin, g)/shrimp shells, g) * 100

The percentage of the yield of chitosan in relation to chitin was

calculated by dividing the weight of produced chitosan to dry chitin

before deacetylation.

Yield was calculated as follows: Yield of chitosan (%) = (produced

chitosan, g)/chitin, g) * 100

The percentage of the final yield of chitosan was calculated by

dividing the weight of produced chitosan to initial dry shrimp shell

weight.

Results

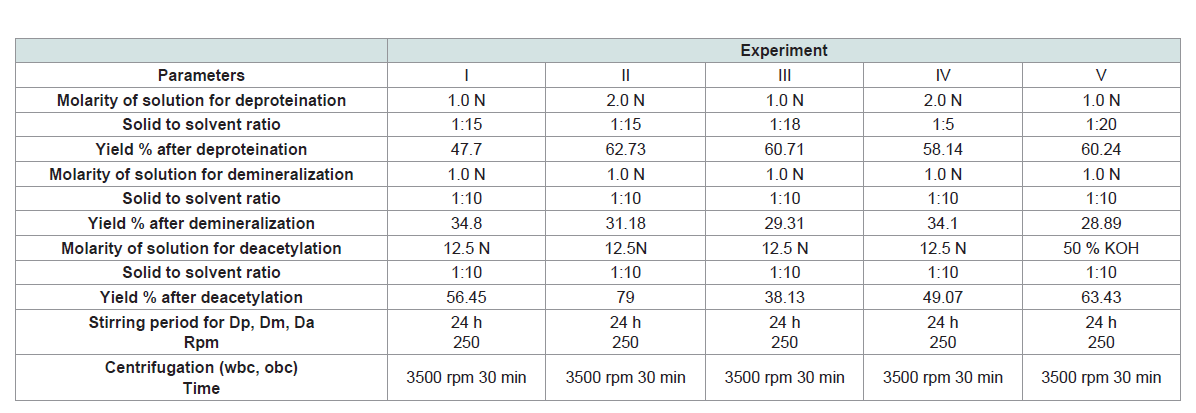

Parameters and details of experiments are demonstrated in

(Table 1). Some differences can be observed attributed to the changes

of molarity of solutions (NaOH, KOH, HCl) for deproteination,

demineralization and deacetylation and to the ratio of solid to solvent. As a result, the percentage of yield differs in all experiments.

The higher values of yield after deproteination were observed in exp

II (62.73) and III (60.71) while the lowest value was observed in exp

I. Also, the percentage of yield after demineralization (as a ratio to

previous step of deproteination), varied from 29% to 35%. The higher

values of yield after demineralization were observed in exp I (34.8),

IV (34.1) and II (31.18) while the lowest value was observed in exp

V (28.89). The percentage of yield after deacetylation (as a ratio to

previous step of demineralization), varied from 38% to 79%. The

higher values of yield after deacetylation were observed in exp II (79)

and V (63.43) while the lowest value was observed in exp III (38.13).

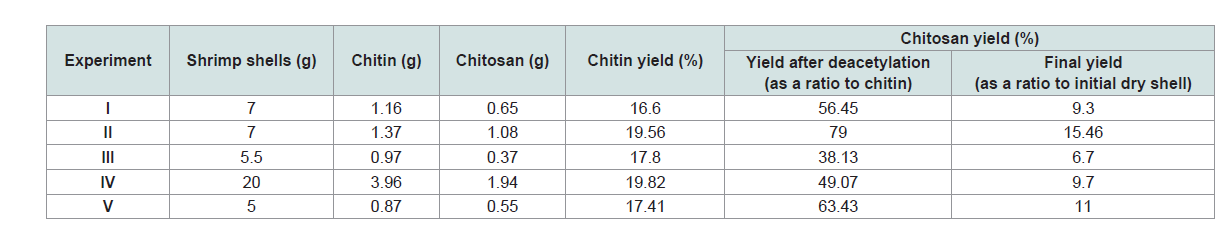

The percentage of yield of chitin and chitosan was presented

in (Table 2). Differences can be observed in the experiments. The

percentage of yield of chitin varied from 16.6 to 19.82, the higher

values were observed in exp II (19.56) and IV (19.82) while the lower

value in exp I (16.6). Also, the percentage of yield of chitosan varied

from 9.3 to 15.46, the higher value was observed in exp II (15.46) and

V (11) while the lower value in exp III (6.7).

Functional and physicochemical properties of chitosan that have

been studied in this work have shown a variety of characteristics as it

is demonstrated in (Table 3). The color of chitosan is whitish slightly

brown while the percentages of water binding capacity and oil

binding capacity are 565 and 384, respectively. Chitosan shows high

solubility in 1% acetic acid (93%) while values of ether extract and ash

are below of 0.5%.

Discussion

Results from this work clearly demonstrate a variety of the

percentage yield of chitin and chitosan. These values note the

importance of the treatments of deproteination, demineralization

and deacetylation and can be attributed to the differences of molarity

of solutions (NaOH, KOH, HCl) and to the ratio of solid to solvent.

Concerning the parameters of the experiments and the percentage

yield it is believed that the extraction process can be improved to gain

higher yields of chitin and chitosan [11-15]. In our experiment results

of 1.0 N solution of HCl for demineralization, 2 N for deproteination

and 12.5 N NaOH solutions for deacetylation at a solid to solvent ratio

of 1:15, clearly demonstrate a significant yield of chitin and chitosan.

Recovery of chitosan in the present study is similar to chitosan yield

(15%) from shrimp shell waste reported by and slightly higher than

yield of chitosan (12%) in study of [16,17].

Functional and physicochemical properties of chitosan indicate

a good quality product with valuable properties[18]. Solubility is

an important property to determine the quality of chitosan; high

solubility refers to a good quality chitosan. Chitosan is soluble in

dilute organic acids, like acetic acid or formic acid and insoluble in

water and in basic pH solutions. Its solubility depends on distribution

of N-acetyl and free amino groups. Chitosan is protonated because of

the presence of amino group in the aqueous acid solution which leads

to its solubility [19]. Also, higher values of solubility are combined

with increasing degree of deacetylation due to removal of acetyl group

from chitin [20]. In our experiments, chitosan showed high solubility

in 1% acetic acid (93%) and its whitish slightly brown color is similar

to color of chitosan of other studies [21]. The higher values of water

and oil binding capacity of chitosan compared with reported studies found to be within the range. Finally, the lower values of the ash and

ether extract content prove the purity of the sample indicating the

completion of demineralization and deproteinization and confirm

the quality of chitosan [22].

Conclusion

In the procedure developed in the present study, chitosan was

obtained as a white slightly brown powder with sufficient functional

physicochemical properties. Improving extraction processes by

changing experiment parameters the yield percentage of chitin and

chitosan could be increased giving an alternative solution in seafood

industries to obtain valuable products.