Journal of Food Processing & Beverages

Download PDF

Research Article

*Address for Correspondence: José de Assis Fonseca Faria, Departamento de Tecnologia de Alimentos, Rua Monteiro Lobato, 80, Caixa Postal 6121, CEP 13083-862, Campinas/SP, Brasil, E-mail: assis@fea.unicamp.br

Citation: Rodrigues Pereira EP, de Assis Fonseca Faria J. Evaluating the use of preservatives and the effect of carbonation on the physicochemical and microbiological stability on coconut water. J Food Processing & Beverages. 2013;1(2): 4.

Copyright © 2013 Assis Fonseca Faria et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use,distribution, and reproduction in any medium, provided the original work is properly cited.

Journal of Food Processing & Beverages | ISSN: 2332-4104 | Volume: 1, Issue: 2

Submission: 11 November 2013 | Accepted: 09 December 2013 | Published: 13 December 2013

Reviewed and approved by: Dr. Kuan-Chen Cheng, Graduate Institute of Food Science and Technology, National Taiwan University, Taiwan

In a study carried out by Pereira et al. [15], the preservatives sodium metabisulfite and potassium sorbate were added after pasteurization, and it was shown that the addition of 40 mg.L-1 sodium metabisulfite plus 260 mg.L-1 potassium sorbate resulted in less variation in the quality attributes of carbonated coconut water samples stored at room temperature, in agreement with the present results.

Evaluating the use of preservatives and the effect of carbonation on the physicochemical and microbiological stability on coconut water

Eliene Penha Rodrigues Pereira and José de Assis Fonseca Faria*

- Departamento de Tecnologia de Alimentos, Rua Monteiro Lobato, 80, Caixa Postal 6121, CEP 13083-862, Campinas/SP, Brasil

*Address for Correspondence: José de Assis Fonseca Faria, Departamento de Tecnologia de Alimentos, Rua Monteiro Lobato, 80, Caixa Postal 6121, CEP 13083-862, Campinas/SP, Brasil, E-mail: assis@fea.unicamp.br

Citation: Rodrigues Pereira EP, de Assis Fonseca Faria J. Evaluating the use of preservatives and the effect of carbonation on the physicochemical and microbiological stability on coconut water. J Food Processing & Beverages. 2013;1(2): 4.

Copyright © 2013 Assis Fonseca Faria et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use,distribution, and reproduction in any medium, provided the original work is properly cited.

Journal of Food Processing & Beverages | ISSN: 2332-4104 | Volume: 1, Issue: 2

Submission: 11 November 2013 | Accepted: 09 December 2013 | Published: 13 December 2013

Reviewed and approved by: Dr. Kuan-Chen Cheng, Graduate Institute of Food Science and Technology, National Taiwan University, Taiwan

Abstract

Consumers usually appreciate coconut (Cocos nucifera) water due to its refreshing qualities and isotonic properties. However, these characteristics are difficult to preserve once the water is extracted from the coconut, because of its rich nutritional composition. Thus in the various industrial processes used for coconut water, the use of additives has been adopted as the technological artifact to increase the required shelf life. In this study it was evaluated the effects of carbonation on the stability of coconut water in combination with the preservatives potassium sorbate and sodium metabisulfite. For the stability studies batches of pasteurized coconut water were filled into plastic bottles and stored at room temperature. The following physicochemical analyses were carried out to evaluate sample quality: carbonation volume, pH, soluble solids, dissolved oxygen and carbon dioxide, acidity, ascorbic acid and the variation in color and turbidity. The total microbiological and yeast and mold counts were also carried out. It was observed that the non-carbonated sample suffered the greatest physicochemical alterations, and samples to which chemical preservatives were also added, after the heat treatment, showed the least variations. None of the samples presented microbial counts during the storage period.Keywords

Coconut Water; Carbonation; Potassium Sorbate; Sodium Metabisulfite; StabilityIntroduction

Usually coconut water is a mildly acid beverage with a pH value of approximately 5.5 which can be from slightly cloudy to transparent with a mildly sweet taste. It is constituted mainly of minerals and sugars and, in smaller proportions, nitrogenated substances (amino acids) and fats, as well as vitamins and auxins (growth promoting substances). Due to its salt-rich composition, it is considered to be a natural isotonic beverage and is highly consumed in Brazil, mainly in natura [1-3].According to Aragão [4], processed coconut water competes on the soft drinks and isotonic beverages market, representing approximately 1.4% of the consumption of this group, estimated in more than 10 billion liters/year. This limited participation on the market shows the size of the possibilities for growth in the consumption of this beverage.

Processed coconut water can be found in the refrigerated form, with a shelf life of approximately 3 days, or frozen with a longer shelf life of up to 6 months. Although one can use simpler packaging systems, such as low density polyethylene (LDPE) or polyethylene terephthalate (PET) cups or bottles, the cost of the cold chain raises the price of the final product.

Room temperature commercialization requires the application of safer systems, such as long-life type cartons, that guarantee protection against the light and oxygen penetration, both highly prejudicial to the product, and more severe heat treatment, such as sterilization. However, this process, in addition to raising the final price, also causes irreversible flavor changes.

While inside the fruit the coconut water is sterile, but its nutrient rich composition favors microbial growth and development, causing problems soon after opening the fruit. Another factor to consider is related to the elevated concentration of naturally present enzymes. These enzymes have specific and vital finalities in the in vivo fruit, but on entering in contact with atmospheric air, undesirable reactions are unleashed, giving rise to a pinkish color [5].

One alternative used to prolong the shelf life of processed coconut water is the use of chemical preservatives, substances capable of inhibiting or retarding microbial growth. However, they are not capable of reducing the microbial count, just of chemically interrupting the microbial cell multiplication process [6,7].

The majority of the chemical preservatives used in foods are of an acid nature, such as, for example, organic acids and their salts, such as the sorbates and benzoates. These preservatives are more effective at pH values ≤ 5.5. Many bacteria are incapable of developing at pH values < 4.5, although many yeasts and molds can grow at pH = 1.6, and hence require greater care [8].

According to Shachman [7], the preservatives most used in carbonated beverages are sodium benzoate (INS 211) and potassium sorbate (INS 202). However, commercially the preservatives most used by coconut water (non-carbonated) processing industries are sodium sulfite (INS 221) and sodium metabisulfite (INS 223).

The act of carbonating coconut water, that is, of injecting carbondioxide (CO2), has been evaluated and concluded that in addition to the sensory factor, this is also capable of exerting an inhibitory effect on bacteria. In general, the microbial inactivation mechanism can be synthesized as: (1) dissolution of the pressurized CO2 in the liquid phase; (2) modification of the cell membrane; (3) decrease of intracellular pH; (4) enzyme inactivation and the inhibition of cell metabolism due to the low pH; (5) effect of the direct inhibition of the CO2 molecules and HCO3- radical on the metabolism; (6) disorder in the intracellular electrolyte balance; (7) removal of vital compounds from the cells and membranes [9].

Therefore, the objectives of this study were to evaluate the stability of coconut water with added potassium sorbate and sodium metabisulfite, carbonated and filled into transparent polyethylene terephthalate (PET) bottles maintained at room temperature.

Materials and Methods

Experimental Design

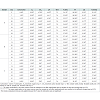

The process was carried out with three coconut water batches, according to the composition shown in See Table 1. For the processing, sample standardization (adjustment of the pH and soluble solids) was carried out before pasteurization. The addition of the preservatives potassium sorbate and sodium metabisulfite to samples was also carried out before pasteurization, whereas for sample B, it received an extra dose of preservatives after the pasteurization. All the samples were evaluated during 54 days of storage at room temperature (25 ± 4°C).

Green coconuts of the dwarf variety with maturity levels of approximately 6 to 7 months were used, all bought from the Central Supply Unit in Campinas - SP (CEASA), Brazil. Refined sugar (Caravelas brand, Usina Colombo, Ariranha - SP, Brazil, used as a source of sucrose) and citric acid (Synth brand, Labsynth, Diadema - SP, Brazil) were used to standardize the coconut water to a 7 °Brix and pH between 4.3 and 4.5. Ascorbic acid (Nuclear brand, Casa da Química, Diadema - SP, Brazil) was added at a concentration of 200mg·L-1, and the chemical preservatives potassium sorbate (Vetec brand, Vetec, Rio de Janeiro - RJ, Brazil) and sodium metabisulfite (Synth brand, Labsynth, Diadema - SP, Brazil), were added according to the experimental design presented in See Table 1.

Transparent polyethylene terephthalate (PET) bottles provided by Minalba (Minalba, São José dos Campos - SP) were used as the packaging system. The characteristics of the bottles were: weight of 16.49 ± 0.05g, volumetric capacity of 348.58 ± 1.32 mL and oxygen permeability of 0.047 ± 0.001 cm3/bottle·day·atm at 25 °C. High density polyethylene screw caps containing Bericap® seal liners (Sorocaba-SP) were used to close the bottles.

Methods

Before extracting the water from the fruits, they were sanitized using a solution of sodium hypochlorite (200 mg·L-1). The water was then standardized to pH between 4.3 and 4.5 and 7 °Brix using citric acid and sucrose. At this point, 200 mg·L-1 of ascorbic acid were added to the water. The drink was clarified by passing through a 1μm pore opening filter, pasteurized at 90 °C for 30 seconds, and rapidly cooled to 2 °C in a plate heat exchanger (model Micro Plak Jr., manufactured by Suma Brand Indústria e Comércio Ltda., Campinas - SP, Brazil), with a nominal flow rate of 300L·h-1, fed with a positive displacement pump (Netzsch brand, Pomerode - SC, Brazil). The coconut water was carbonated to 2 to 3 volumes in a carbonating machine developed by Faria [10]. This step consisted of injecting carbon dioxide into the beverage under pressure to obtain the desired degree of carbonation. The drink was packaged into PET bottles, previously cleaned with a sodium hypochlorite solution (200 mg·L-1) and stored at room temperature (25 ± 3 °C) for 54 days.

Evaluation of stability

To evaluate the stability, the carbonation volume was analyzed according to the ASTM F1115-95 standards [11]; the pH was determined using a Digimed potentiometer (Sao Paulo - SP, Brazil), model DM-20 at 25 °C; the soluble solids using a portable refractometer (Optech, model RCZ, Guarulhos - SP, Brazil); dissolved O2 assessed using an O2 meter (Mettler Toledo, model MO128, Barueri - SP, Brazil); and dissolved CO2 using a CO2 electrode (Thermo Scientific, model Orion 720A-represented in Brazil by Analyser, Sao Paulo - SP). The color and turbidity parameters were determined in a colorimeter (Hunterlab, model Colorquest ll, using the CIELAB system with the illuminant D65, observer’s angle of 10°, TTRAN-type calibration and HAZE measurement).

Titratable acidity was determined based on AOAC method 942.15 [12]. The ascorbic acid concentration was determined by titrating 10mL of sample with 50mL of a 1% oxalic acid solution standardized with a solution of 2g·L-1 dichloroindophenol (DCFI).

For the microbiological evaluations, the total aerobic plate count was obtained by pour plating 1mL of each dilution into Plate Count Agar (PCA). The colonies were counted after 48 hours of incubation at 35 °C and expressed as Colony Forming Units per mL (CFU·mL-1). The yeast and mould count was obtained by surface plating 1mL of each dilution in Potato Dextrose Agar (PDA) and counting after 5 days at 23 °C [13]. The microbiological evaluation was carried out at zero time and after 54 days of storage.

Statistical Analysis

The analyses of the processed coconut water were carried out in triplicate. The analysis of variance (ANOVA) was used to determine significant differences (P < 0.01) between different coconut water treatments (A, B and C) for every parameter on the same day, and between different storage days for each sample. Following ANOVA, Tukey’s means comparisons test was used to assess differences between the means. The software Statistical Analysis System Version 9.2 (SAS) was used in the statistical calculations [14].

Results and Discussion

The Table 2 shows the results obtained after 54 days of storage at room temperature. The results show that sample C, which was not carbonated, presented greater variations in the attributes analyzed, showing greater variation in color and turbidity in relation to the other two samples. It also showed a drastic decrease in the ascorbic acid content. Samples A and B showed small variations in the attributes throughout storage, sample B presenting less variation in color and ascorbic acid.

The samples showed no variations in the microbiological evaluations throughout storage. The total microbial count for the three samples at the start and end of the storage period was < 1.0 CFU.mL-1, and the yeast and mold count < 10 CFU.mL-1.

Conclusion

The use of carbonation presented a positive effect since it increased the physicochemical storage stability of coconut water, but no effect was observed on microbial counts, probably because of the combined protection given by the pasteurization and added preservatives. Also, this study showed that the addition of CO2 to the coconut water, besides giving a more refreshing sensation to the beverage, also contributed to its conservation because it helped to reduce the product’s pH, as well as the amount of dissolved oxygen.References

- Medina JC, Garcia JLM, Martin ZJ, Kato K, Teruo P, et al. (1980) Coco: da Cultura ao Processamento e Comercialização. Série Frutas Tropicais, Campinas, ITAL.

- Maciel MI, Oliveira SL, Silva IP (1992) Effects of Different Storage Conditions on Preservation of Coconut (Cocus nucifera) water. J Food Process Preserv 16: 13-22.

- Campos CF, Souza PEA, Coelho JF, Glória MBA (1996) Chemical composition, enzyme activity and effect of enzyme inactivation of flavor quality of green coconut water. J Food Process Preserv 20: 487-500.

- Aragão WM (2007) A Cultura do Coqueiro. Embrapa Tabuleiros Costeiros, Aracajú.

- Rosa MF, Abreu FAP (2000)Água de Coco: Métodos de Conservação.

- Mitchell AJ (1990) Formulation and Production of Carbonated Soft Drinks. Blackie and Son Ltd, New York.

- Shachman M (2005) The Soft Drinks Companion: A Technical Handbook for the Beverage Industry. Crc Press, Boca Raton.

- Russel NJ, Gould GW (2003) Food Preservatives. Kluwer Academic, (2nd edtn), New York.

- Garcia-Gonzalez L, Geeraerd AH, Spilimbergo S, Elst K, Van Ginneken L, et al. (2007) High Pressure Carbon Dioxide Inactivation of Microorganisms in Food: The Past, the Present and the Future. Int J Food Microbiol 117: 1-28.

- Faria JAF (2007) Professor Titular do Departamento de Tecnologia de Alimentos da Faculdade de Engenharia de Alimentos da Unicamp. Carbonatador de bebidas, Campinas.

- American Society for Testing and Materials - ASTM (2001) ASTM F1115-95: Standard Test Method for Determining the Carbon Dioxide Loss of Beverage Containers. West Conshohocken: 1-12.

- AOAC (1997) Official Methods of Analysis of AOAC International. Gaithersburg: 16 ed.

- Silva N, Junqueira VCA, Silveira NFA (2001) Manual de Métodos de Análises Microbiológicas de Alimentos. Editora Varela, Campinas.

- SAS Institute Inc (1992) SAS User’s Guide: Statistics Version 9.2, SAS Institute Inc, Cary, NC, USA.

- Pereira EPR, Faria JAF, Pinto UM (2013) Optimizing the Use of Potassium Sorbate and Sodium Metabisulphite for the Chemical and Microbial Stability of Carbonated Coconut Water. Braz J Food Technol 16:125-132.